Within the sphere of manufacturing procedures, protecting the stability and functionality of lines is necessary. Amassing of impurities within conduits can considerably impair fluid dynamics, degrade commodity standard, and adds to maintenance outlays. To handle these difficulties, duct washing systems have appeared as extremely efficient solutions for fluid duct cleansing. A device, typically a rod-like apparatus, is driven through the passage, skillfully cleaning deposits and accomplishing best productivity

Line purification frameworks grant several positive points. They are modifiable, fit for scouring lines of varied thicknesses and materials. Furthermore, they are potent, finishing the mission in a reasonably quick term. By lessening downtime and strengthening pipeline output, pipeline cleaning systems foster expenditure savings and increased operational performance

Cleanliness Pipeline Practices:

Upholding pipeline spotlessness is required for ensuring item safety and excellence of carried materials. Sanitary pigging systems supply a consistent way to accomplish this goal. Pigs, specific instruments, are put in into pipelines to scrub by displacing residues and waste

- Various classes of sanitary pigs are accessible, each designed for distinct cleaning needs.

- These pigs are developed from ingredients that comply with stringent safe standards.

- Systematic sanitary pigging operations facilitate preventing product meaning loss, maintain pipeline functional period, and increase holistic operation.

Advanced Pigging Technologies for Maximum Functionality

Amid the territory of conduit upkeep, innovative pigging techniques have turned into a fundamental asset for providing best functionality and defense. These groundbreaking systems leverage clever blueprints and interactions to proficiently clean, inspect, and protect pipelines from damage. From smart pigs equipped with up-to-date assessment attributes to engineered pigging apparatus purposed for detailed tasks, development in this discipline is constantly raising bars. By embracing these advancements, managers can greatly enhance pipeline integrity, reduce downtime, and increase operational performance.

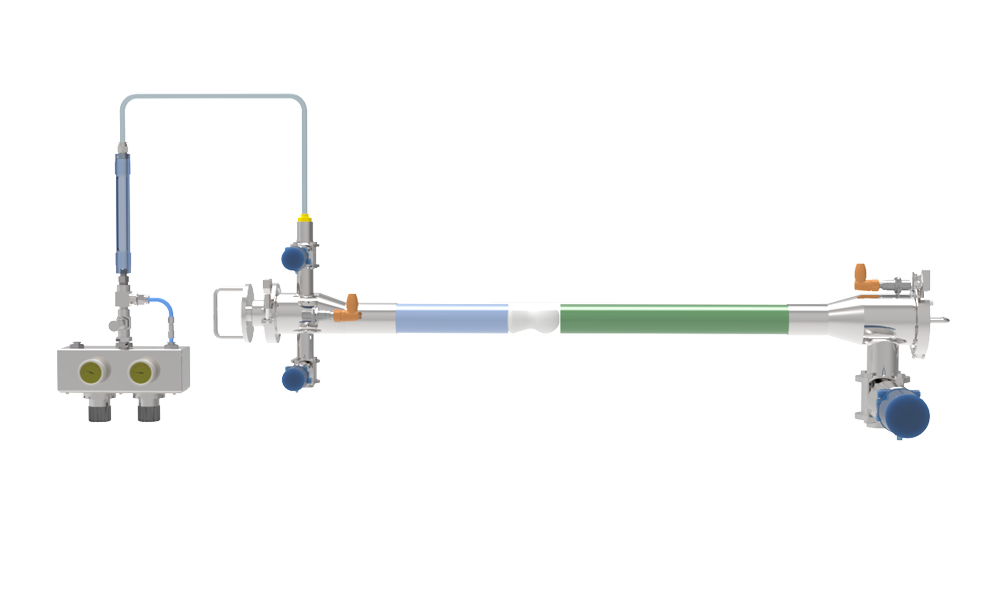

Extensive Pigging Setup Design and Deployment

Such wide-ranging pigging system consists of a central procedure for pipeline management. This system entails the placement of allocated tools called pigs, which advance through tubes to disinfect, review, and safeguard their stability. The layout puts weight on variables such as line size, makeup, pig form, and operational needs. A well-designed system confirms robust pigging functions while limiting downtime and potential injuries. Installation customs necessitate careful coordination, skilled professionals, and strict adherence to safety standards to confirm a protected and successful achievement

Manufacturing Pigging Appliances for Varied Applications

Factory pigging equipment are indispensable mechanisms used across a ample range of industries. These equipment promote satisfactory and successful cleaning, monitoring, and upkeep of ducts and other hollow edifices. Pigging entails installing specialized gizmos known as pigs through pipes to perform various functions. Regular types of industrial pigging gadgets consist of cleaning pigs, inspection pigs, and transit pigs. Cleaning pigs are designed to take out debris, build-up, and residues from pipelines. Inspection pigs are loaded with devices that retrieve information about the shape of pipe bases. Transport pigs are functional to deliver contents through pipelines. The use of industrial pigging products grants numerous merits, such as reduced downtime, reinforced pipeline soundness, and reinforced operational productivity. These devices are broadly applied in branches such as oil and gas, water treatment, chemical production, and food manufacturing.Extensive Pipeline Pigging Manual

Pipeline pigging is an fundamental procedure used within the oil and gas arena to maintain pipelines. This vital assignment consists of introducing tailored gadgets, dubbed pigs, into the conduit. Pigs are built to navigate the track of the pipeline, carrying out various duties.

Some versions of pigs are available, each designed for a unique function. Common exercises of pipeline pigging consist of surveying for defects, cleaning, and corrosion control.

- Gains of Pipeline Pigging

- Repercussions on Operational Efficiency

- Varieties of Pipeline Pigs

Efficient Sanitation utilizing Pigging Setups

Pigging solutions furnish a stable answer for maintaining sanitation inside tubes. These frameworks incorporate dedicated units that proceed through the conduit setup, adroitly scrubbing fouling. The operation is especially helpful for areas that necessitate rigorous sanitation standards. Pigging systems contribute a value-for-money and fast approach for washing ducts, mitigating the chance of contamination.

Selecting Pigging Hardware for Custom Specifications

Pigging tools fulfills a crucial role in best pipeline work. When opting for pigging tools, it is essential to consider the distinct requests of your task. This involves checking features such as pipeline width, flow current, product style, and repair requirements.

Countless pigging models are available, each developed for distinct reasons. As an example, some pigs are developed for assessment, while others are deployed for eliminating pollutants or segmenting product groups.

What's more, pigging devices components should be matching with the carried content.

It is generally best to liaise with a expert in pigging practices to verify that you adopt the most fitting equipment for your customized requirements.

Pigging Systems - A Result-Oriented Approach

Pipeline tools grant a wide choice of benefits for markets dependent on lines. By aptly purging and surveying tube insides, pigging systems raise operational capability and curtail maintenance budgets.

A leading pro of pigging systems is their capacity to extract scale such as crust, debris, and deterioration byproducts. This regular cleaning guarantees steady pipeline flow and deters costly downtime.

What's more, pigging systems can be operated to inspect the status of pipelines, revealing potential defects before they amplify into extensive concerns. This anticipatory plan boosts to extend the lifespan of pipelines and minimize overall maintenance budgets.

Preserving Hygiene in Pigging Workflows

Pig husbandry methods essentially emphasize appropriate hygiene protocols to minimize the circulation of contagions. Complying with rigorous hygiene requirements enhances a healthy atmosphere for pigs, that contributes to enhanced health outcomes and performance.

Systematic cleaning and disinfection of enclosures is mandatory to restrain the volume of harmful contaminants. Satisfactory discard management likewise fulfills a primary part in upholding hygiene.

As pigging systems well, {workers