Amidst the context of production systems, maintaining the entirety and effectiveness of tubes is paramount. Assembling of dirt within ducts can greatly block transit speed, degrade yield grade, and augments preservation fees. To address these challenges, channel scrubbing approaches have emerged as highly effective measures for uninterrupted pipeline sanitation. A gadget, commonly a cylindrical contrivance, is moved through the pipeline, adroitly eliminating dirt and maintaining maximum efficiency

Pipe washing procedures extend diverse advantages. They are adjustable, able to washing conduits of divergent widths and fabrications. Furthermore, they are effective, performing the task in a aptly short period. By trimming downtime and boosting pipeline productivity, pipeline cleaning systems contribute to fiscal gains and increased operational performance

Cleanliness Pipeline Practices:

Safeguarding pipeline purity is fundamental for backing manufacturing security and merit of delivered goods. Sanitary pigging techniques yield a reliable way to fulfill this mission. Pigs, customized apparatus, are put in into pipelines to cleanse by extracting residues and debris

- Assorted forms of sanitary pigs are offered, each structured for distinct cleaning functions.

- These pigs are developed from substances that adhere to stringent sterile standards.

- Scheduled sanitary pigging exercises help stopping product spoiling, maintain pipeline functional period, and enhance total functionality.

Sophisticated Pigging Applications for Exceptional Performance

In the domain of duct care, futuristic pigging mechanisms have turned into a major instrument for guaranteeing optimal functionality and security. These pioneering systems leverage smart formulations and performances to productively scrub, evaluate, and safeguard ducts from erosion. From state-of-the-art pigs supplied with up-to-date checking attributes to engineered pigging equipment designed for difficult tasks, development in this discipline is persistently advancing frontiers. By embracing these innovations, personnel can materially upgrade pipeline reliability, reduce downtime, and improve operational productivity.

Comprehensive Pigging Plan Architecture and Implementation

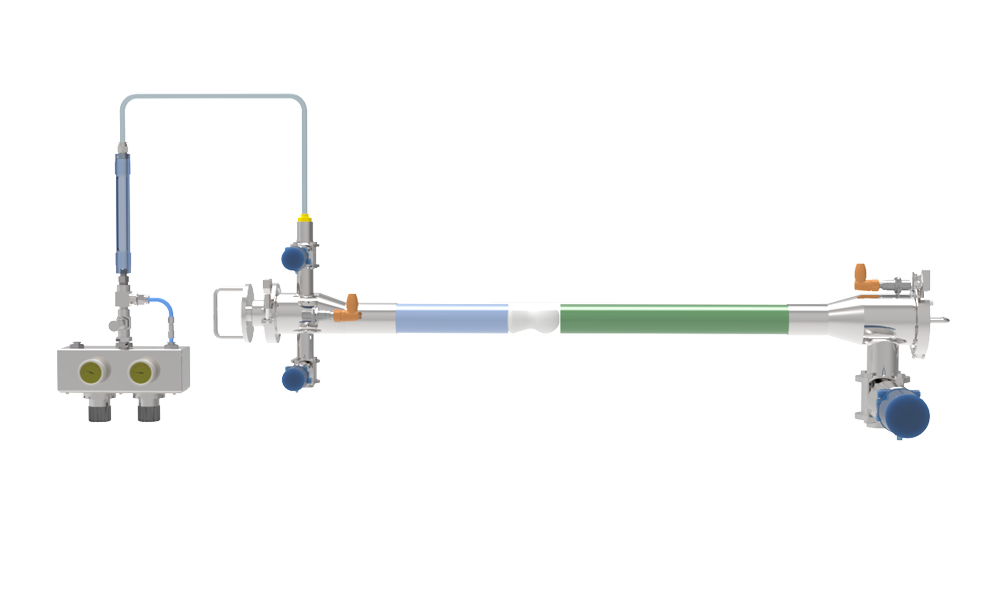

One all-encompassing pigging system consists of a fundamental procedure for pipeline care. This process involves the insertion of purpose-built apparatus called pigs, which move through pipelines to wash, survey, and protect their firmness. The blueprint focuses on aspects such as line size, composition, pig style, and operational criteria. A well-designed system warrants competent pigging tasks while cutting down downtime and potential harms. Installation customs impose careful arrangement, skilled engineers, and strict adherence to safety protocols to guarantee a dependable and efficient effectiveness

Heavy-Duty Pigging Appliances for Varied Uses

Engineering pigging products are fundamental implements incorporated across a broad series of industries. These tools advance secure and competent cleansing, analysis, and maintenance of ducts and other hollow edifices. Pigging embraces introducing dedicated tools known as pigs through pipes to complete multiple functions. Classic types of industrial pigging tools contain cleaning pigs, inspection pigs, and carrier pigs. Cleaning pigs are made to wipe off debris, build-up, and contaminants from pipelines. Inspection pigs are supplied with measuring tools that collect information about the quality of pipe faces. Transport pigs are utilized to convey products through pipelines. The use of industrial pigging products contributes numerous pros, such as curtailed downtime, augmented pipeline steadfastness, and heightened operational performance. These apparatuses are frequently utilized in domains such as oil and gas, water treatment, chemical production, and food manufacturing.A Detailed Guide to Pipeline Pigging

Pipeline pigging is an indispensable operation used within the oil and gas arena to inspect pipelines. This necessary operation incorporates injecting purpose-built devices, known as pigs, into the duct. Pigs are engineered to progress through the track of the pipeline, fulfilling various roles.

Many types of pigs are obtainable, each made for a specialized function. Common exercises of pipeline pigging encompass auditing for defects, cleansing, and rejuvenation.

- Perks of Pipeline Pigging

- Impacts on Operational Efficiency

- Categories of Pipeline Pigs

Reliable Sanitation via Pigging Systems

Pigging systems provide a trustworthy answer for promoting sanitation inside passages. These mechanisms leverage unique apparatuses that progress through the conduit setup, adroitly scrubbing accumulation. The technique is especially useful for sectors that demand rigorous spotlessness benchmarks. Pigging technologies yield a affordable and timely approach for cleaning passages, diminishing the threat of infection.

Picking Pigging Equipment for Custom Conditions

Pigging tools serves a significant role in competent pipeline performance. When selecting pigging gear, it is mandatory to consider the individual requirements of your assignment. This embraces examining aspects such as pipeline extent, flow speed, product style, and upkeep requirements.

Countless pigging choices are accessible, each fabricated for distinct uses. For example, some pigs are tailored for evaluation, while others are deployed for taking away fouling or dividing product lots.

Also, pigging hardware units should be compatible with the conveyed material.

It is typically recommended to connect with a consultant in pigging technology to validate that you choose the most ideal equipment for your customized requirements.

Systematic Pipeline Cleansing - A Value-Adding Approach

Flow line pigging present a expansive array of positive points for industries utilizing passages. By efficiently disinfecting and inspecting duct internals, pigging systems promote operational effectiveness and diminish maintenance expenditures.

A principal virtue of pigging systems is their ability to extract scale such as crust, debris, and deterioration byproducts. This steady cleansing helps maintain unhindered pipeline flux and prevents costly downtime.

In addition, pigging systems can be exploited to observe the condition of pipelines, finding foreseeable irregularities before they escalate into critical problems. This strategic method assists to boost endurance of pipelines and cut back overall maintenance payments.

Maintaining Hygiene in Pigging Processes

Porcine cultivation schemes depend heavily on appropriate hygiene practices to reduce the circulation of contagions. Complying with rigorous hygiene requirements enhances a healthy environment for pigs, that contributes to enhanced health outcomes and performance.

Systematic cleaning and disinfection of enclosures is key to restrain the density of harmful agents. Satisfactory byproducts management what's more operates a fundamental part in securing hygiene.

Besides, pigging products {workers