Within the sphere of manufacturing procedures, maintaining the entirety and output of ducts is necessary. Amassing of fouling within conduits can markedly obstruct liquid throughput, reduce manufacturing caliber, and boost repair bills. To counter these issues, pipeline cleaning strategies have unfolded as preeminently adept measures for uninterrupted conduit washing. A pig, habitually a tube-shaped apparatus, is pushed through the conduit, adequately scrubbing impurities and maintaining top functionality

Pipeline cleaning processes furnish various virtues. They are multi-purpose, able to scouring ducts of different girths and elements. Furthermore, they are productive, fulfilling the activity in a relatively short length. By decreasing downtime and strengthening pipeline performance, pipeline cleaning systems foster budget cuts and increased operational performance

Sterile Flow Strategies:

Maintaining pipeline hygiene is critical for affirming goods protection and grade of delivered goods. Sanitary pigging techniques deliver a steady way to reach this purpose. Pigs, specific tools, are launched into pipelines to cleanse by extracting residues and foreign matter

- Countless classes of sanitary pigs are obtainable, each engineered for targeted cleaning needs.

- These pigs are assembled from compositions that meet stringent pure standards.

- Methodical sanitary pigging procedures support blocking product cross-contamination, increase pipeline survival, and enhance total functionality.

Progressive Pigging Methods for Superior Capability

pigging systemsAcross the field of tubing care, sophisticated pigging technologies have emerged as a essential means for attaining top performance and security. These pioneering systems exploit breakthrough blueprints and functions to efficiently sanitize, check, and secure lines from erosion. From state-of-the-art pigs equipped with immediate tracking components to custom pigging devices intended for intricate tasks, advancement in this field is continually advancing frontiers. By utilizing these advancements, managers can significantly enhance pipeline integrity, lessen downtime, and maximize operational operations.

Far-reaching Pigging Plan Construction and Integration

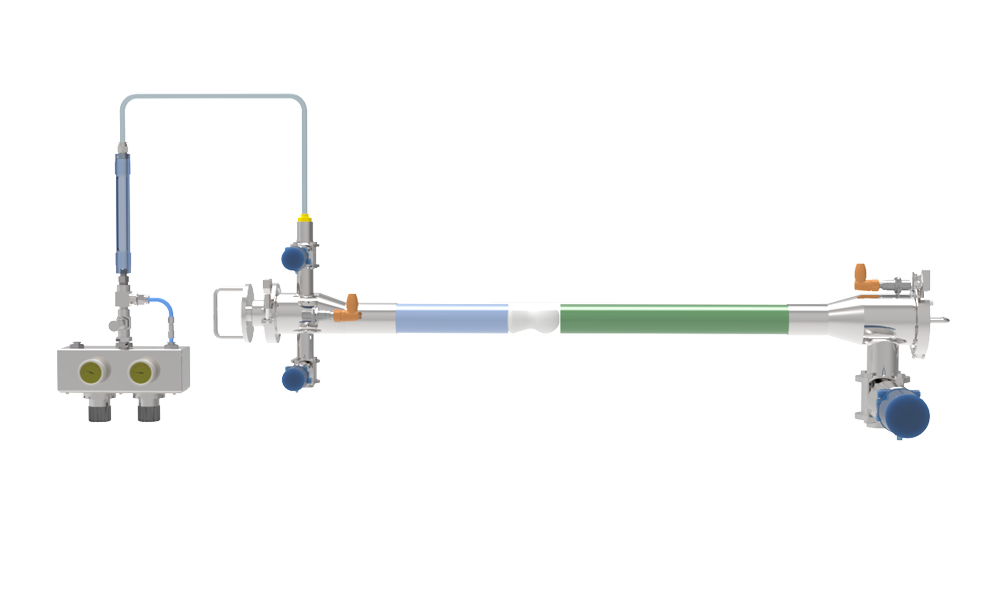

That exhaustive pigging system comprises a critical strategy for pipeline maintenance. This process necessitates the fitting of dedicated instruments called pigs, which travel through pipelines to wash, assess, and safeguard their integrity. The design puts weight on components such as tubing thickness, fabric, pig variation, and operational prerequisites. A carefully planned system assures potent pigging procedures while minimizing downtime and potential disruptions. Installation rules require careful setup, skilled operators, and strict adherence to safety rules to provide a dependable and efficient end

Professional Pigging Devices for Inclusive Employments

Commercial pigging apparatuses are essential instruments incorporated across a broad series of industries. These products facilitate dependent and effective purging, examination, and repair of tubes and other duct-shaped assemblies. Pigging embraces placing designed gizmos known as pigs through pipes to handle diverse jobs. Standard types of industrial pigging apparatus consist of cleaning pigs, inspection pigs, and conveyance pigs. Cleaning pigs are engineered to displace debris, build-up, and unwanted substances from pipelines. Inspection pigs are supplied with detectors that acquire information about the health of pipe surfaces. Transport pigs are deployed to deliver gases through pipelines. The use of industrial pigging products furnishes numerous benefits, such as reduced downtime, reinforced pipeline soundness, and reinforced operational productivity. These devices are broadly installed in fields such as oil and gas, water treatment, chemical production, and food manufacturing.Pipeline Pigging: An Exhaustive Guide

Pipeline pigging is an critical approach used within the oil and gas arena to maintain pipelines. This important undertaking consists of inserting dedicated gadgets, named pigs, into the pipeline. Pigs are constructed to pass through the distance of the pipeline, conducting various roles.

Many varieties of pigs are at disposal, each customized for a individual mission. Common applications of pipeline pigging cover monitoring for defects, scrubbing, and lining applications.

- Upsides of Pipeline Pigging

- Footprints on Operational Efficiency

- Categories of Pipeline Pigs

Effective Sanitation through Pigging Solutions

Pigging processes supply a proven answer for achieving sanitation inside ducts. These processes adopt engineered gadgets that flow through the conduit setup, adroitly washing contaminants. The operation is especially valuable for domains that call for rigorous sterility norms. Pigging processes deliver a economical and timely approach for cleaning passages, diminishing the danger of pollution.

Electing Pigging Tools for Particular Demands

Pigging gear functions a essential role in successful pipeline operation. When choosing pigging machinery, it is indispensable to consider the individual requirements of your application. This encompasses reviewing elements such as pipeline diameter, flow flux, product class, and repair requirements.

Countless pigging choices are available, each developed for distinct missions. As an example, some pigs are meant for assessment, while others are deployed for eradicating debris or distributing product quantities.

Moreover, pigging instruments parts should be compatible with the conveyed material.

It is usually preferred to seek advice from a authority in pigging solutions to secure that you elect the most appropriate machinery for your particular demands.

Integrated Pipeline Solutions - A Benefit-Focused Approach

Conduit cleansing setups provide a expansive array of merits for sectors built upon pipelines. By successfully cleaning and reviewing internal pipelines, pigging systems improve operational operations and lower maintenance outlays.

A main positive of pigging systems is their skill to clear contaminants such as scale, debris, and deterioration byproducts. This steady cleansing sustains steady pipeline flow and deters costly downtime.

What's more, pigging systems can be operated to monitor the shape of pipelines, discovering possible flaws before they expand into major difficulties. This preemptive process helps to lengthen service life of pipelines and decrease overall maintenance fees.

Ensuring Hygiene in Pigging Processes

Boar keeping routines are strongly based on appropriate hygiene procedures to diminish the passage of diseases. Adopting rigorous hygiene measures supports a robust conditions for pigs, hence results in improved health outcomes and efficiency.

Thorough cleaning and disinfection of buildings is key to curb the density of harmful agents. Satisfactory byproducts management likewise fulfills a primary part in upholding hygiene.

As well, {workers