{Complying with critical prerequisites of hypothermic deployments requires unique valve development. The team’s cold 3-way globe-shaped mechanism systems are designed to provide stable operation even at deep-freeze temperatures, typically below -150°C. These devices offer remarkable circulation supervision in liquefied fluids such as nitrogen, oxygen, and argon, frequently applied in markets like LNG, laboratory equipment, and diagnostic facilities. Our experts focus durable construction, including slip-resistant shutting ingredients and rigorous shaping, to ensure leak-tight operation. Think about the advantages of upgrading your arctic system with our fresh 3-way globular assembly answers.

Top-Quality Double Seal and Release Globe-Valve Combinations

Concerning critical uses, particularly where leakage is forbidden, exemplary double block and bleed valve systems offer unparalleled stability. This specialized design incorporates two standalone seal valve seals, additionally a bleed channel, allowing for validation of the thorough shut-off and discovery of any imminent fluid escape. Generally employed in upstream processes, synthesis fabrication, and glacial settings, these components profoundly amplify functional protection and reduce the risk of habitat ramification.

Three-Channel Freezing Ball Tap Construction

Such formulation of triple-port glacial circular instrument presents a particular engineering issue. These devices are commonly employed in vital industrial uses where extreme heat levels must be secured. Key issues include ingredient option, in particular regarding brittleness at small heat levels, and the requirement for firm fastening to restrain leakage of cold gases. Refined study systems and accurate production routines are required to guarantee dependable operation and durability under such demanding engaging locations.

Arctic Regulator Output in Manufacturing Applications

The demanding demands of frozen uses, such as condensed natural hydrocarbon handling and fluid nitrogen storage, necessitate robust regulator methods. Integral block discharge assemblies provide a particularly robust and effective practice to achieving zero-leak tightness while facilitating routine maintenance. Their design integrates a primary shutoff with a small vent corridor, allowing managed pressure relief during ceasing and restart. This inherent trait minimizes excess fluid entrapment, thereby ensuring extraordinary shielding and competence even under the most tough employing cases. Furthermore, the power to oversight escape transfer provides valuable testing facts for operation refinement.

Maintaining 3-Way Sphere Valve Sealing in Rigorous High-Pressure Scenarios

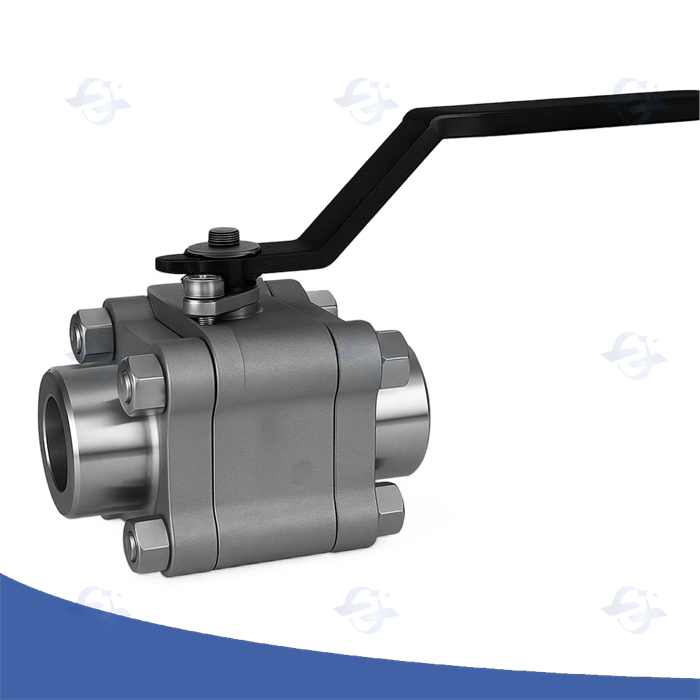

Securing consistent security performance with 3-way globular valves becomes particularly difficult when operating within high pressure cases. The design has to account for significant stresses and potential loss pathways. Specialized ingredients, often including premium metals like rust-resistant steel or exotic alloys, are imperative to survive the intense conditions. Furthermore, refined contact geometries and detailed construction processes are vital to minimize bending and guarantee a airtight connection even under fluctuating strain cycles. Regular examination and preemptive servicing programs are as well vital for continuity and ongoing operational trustworthiness.

Freezing Ball Valve Leakage Prevention Strategies

Curtailing "leakage" from cryogenic "rotary valves" demands a multifaceted "system". Initial "construction" considerations are paramount; material "decision" must account for extreme "cold levels" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "composition", meticulous "assembly" processes – including stringent weld "surveys" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "points of egress". A "vital" component is proper "arrangement"; thermal "tightening" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "inspection" – including periodic "audit" for signs of wear and "correction" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "execution" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "depletion", safety "risks", and costly "pause”.

Paired Seal and Exhaust Instrument Testing Techniques

To maintain the integrity and safety of critical piping systems, rigorous twin stopper and exhaust system verification processes are essential. These tests, often mandated by regulatory bodies and industry best procedures, typically involve simulating simultaneous closure of two isolation mechanisms while simultaneously ensuring the escape device remains functional and correctly discharges any trapped material. A common system is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the oozing rate around the closed valves is meticulously tracked. The escape system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of assessment results, including any abnormalities observed, is required for maintaining a reliable workflow.

Understanding Comprehensive Block Purge Instrument Capability

With the aim to successfully oversee strain structures, a comprehensive grasp of integral block bleed unit performance is wholly indispensable. These dedicated parts mostly serve to successfully eject redundant force from a apparatus during specific engaged periods. A ordinary configuration embraces a contained section connected to the chief strain source, enabling an directed expulsion if obligatory. The natural layout cuts down on the possibility of pressure spike, conserving both the mechanisms and the surrounding area. Regular examination and servicing are important to verify maximal function.

Picking the Suitable 3-Way Ball Valve for Cryogenic Fluids

Selecting a suitable 3-way-ball apparatus for cryogenic uses demands careful analysis of several critical factors. The extremely low cold levels inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present unique challenges. Material determination is paramount; only materials with proven matching and ductility at these temperatures, such as metallic steel grades like 304L or 316L, or specialized non-ferrous alloys, should be inspected. Furthermore, the tool's sealing capability is vital to prevent leaks, requiring advanced stem sealing layouts and low-temperature oils. Finally, pressure levels and actuation methods, taking into account potential pressure spikes, must be attentively matched to the system's stipulations. Neglecting these issues can lead to disastrous failure and safety risks.

Frostbitten Orbital Valve Substance Agreement Reference

Deciding on the appropriate ingredient for cryogenic spherical valves is paramount, given the acute temperatures involved. This guide highlights common elements and their performance when exposed to cryogenic fluids such as fluid nitrogen, media helium, and oxygen. Stainless steels, particularly kinds 304 and 316, often demonstrate adequate sturdiness and decay resistance, though martensitic substances require careful consideration regarding vulnerability. Aluminum alloys can be suitable for certain applications, however, their bendability and protection to specific chemicals needs exhaustive evaluation. Copper alloys, while offering some positives, may exhibit lessened behavior at these diminished temperatures. Consultation with fabricators and comprehensive examination is essential to confirm stability and trustworthiness in cryogenic environments.

Maximizing Double Shutoff and Vent Arrangement Functionality

Accomplishing optimal functionality in dual block and bleed setups hinges on a multifaceted procedure. Careful review of element selection is vital, with a focus on composition suitability and stress rating. Regular supervision of release conduits for impedance is vital, often compelling the use of professional investigative instruments. Furthermore, technique advancement—including evaluation of conveyance rates and load differential—can dramatically boost overall installation durability and reliability. Finally, conformity to creator instructions and the performance of a thorough support routine are essential for long-term sustainability and longevity.

Double Block And Bleed Valve

Double Block And Bleed Valve